How to Choose the Right Acrylic Sheet for Your Needs

# How to Choose the Right Acrylic Sheet for Your Needs

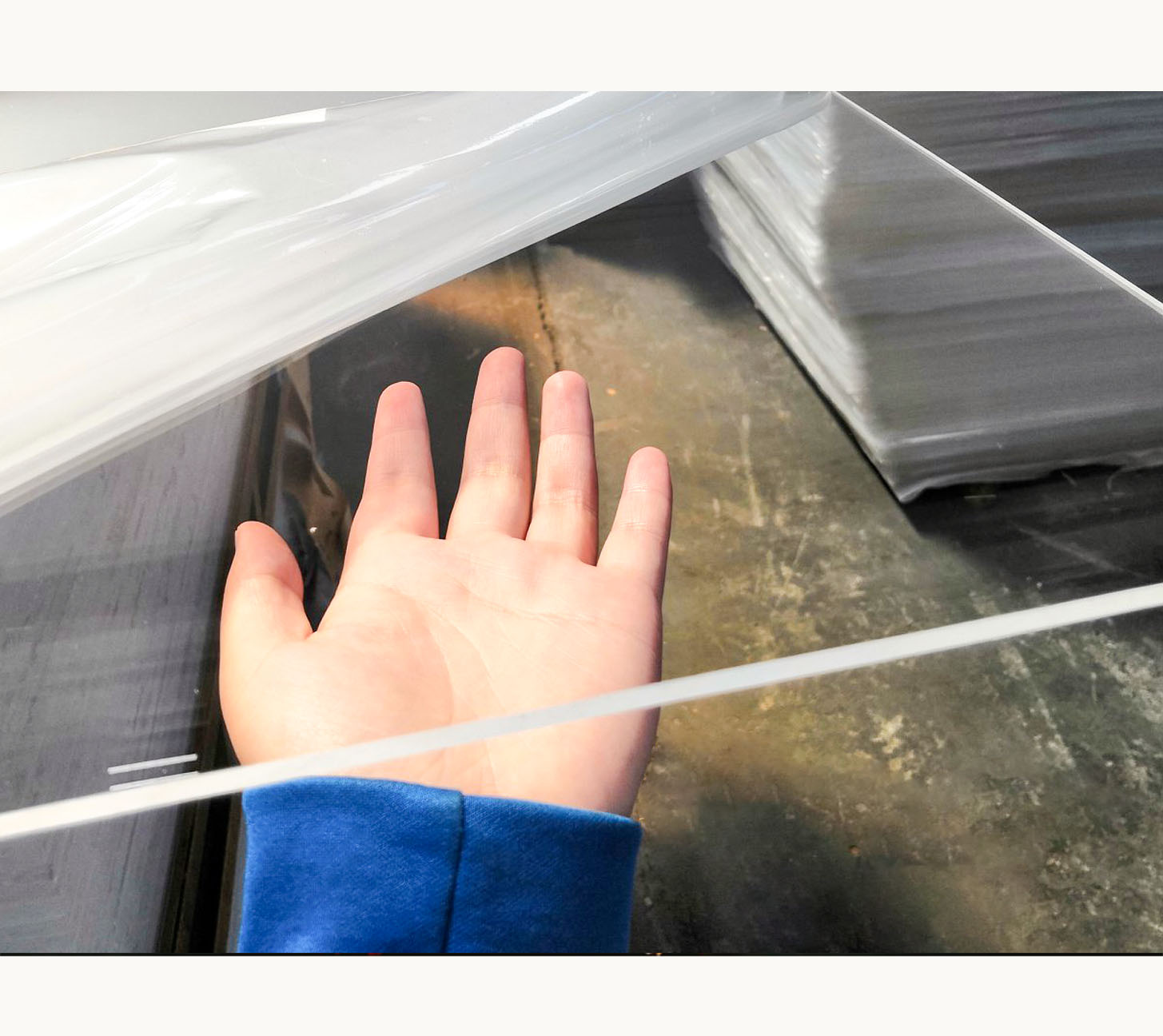

Selecting the perfect acrylic sheet for your project can be a daunting task given the wide variety available. Acrylic sheets, known for their versatility, durability, and clarity, are used in numerous applications, from crafting and DIY projects to industrial manufacturing. Here’s a comprehensive guide to help you choose the right acrylic sheet for your needs.

## 1. Understand Your Project Requirements

### **Identify the Application**

First and foremost, understand the specific needs of your project. Are you using acrylic for a display case, signage, window glazing, or an artistic piece? The application determines the type, thickness, and quality of acrylic you need.

### **Indoor vs. Outdoor Use**

Consider whether the acrylic will be used indoors or outdoors. Outdoor applications require UV-resistant acrylic to prevent yellowing and degradation from prolonged sun exposure.

## 2. Types of Acrylic Sheets

### **Cast Acrylic Sheets**

Cast acrylic is known for its superior optical clarity, greater chemical resistance, and better machining properties. It’s ideal for applications requiring high-quality finish and durability, such as aquariums and optical devices.

### **Extruded Acrylic Sheets**

Extruded acrylic is more cost-effective and consistent in thickness, making it suitable for applications where precision is less critical. It’s easier to thermoform and bond, perfect for signage and protective barriers.

## 3. Thickness Considerations

### **Structural Integrity**

The thickness of the acrylic sheet affects its structural integrity. For high-impact applications, such as protective barriers or furniture, opt for thicker sheets (usually 6mm or more). Thinner sheets (2-3mm) are adequate for lightweight, non-load-bearing applications like photo frames and display cases.

### **Weight and Flexibility**

Thicker sheets are heavier and less flexible. Consider the weight if your project requires frequent handling or transportation. For applications needing flexibility, like curved surfaces, thinner sheets are preferable.

## 4. Color and Finish

### **Clear vs. Colored Acrylic**

Clear acrylic is the most popular due to its glass-like appearance and transparency. Colored acrylic sheets, available in a range of hues, can add a decorative touch to projects like signage, displays, and interior design elements.

### **Glossy vs. Matte Finish**

Glossy acrylic sheets offer a shiny, reflective surface, enhancing the visual appeal of displays and decorative items. Matte finish acrylic reduces glare, making it suitable for applications like screens and signage where readability is crucial.

## 5. Special Properties

### **UV Protection**

For outdoor use, ensure the acrylic sheet has UV protection to prevent yellowing and brittleness over time. UV-resistant acrylic is essential for longevity in sun-exposed environments.

### **Anti-Static and Anti-Reflective Coatings**

Consider acrylic sheets with special coatings for specific applications. Anti-static acrylic is useful in electronics and cleanroom environments, while anti-reflective coatings improve visibility for displays and screens.

## 6. Budget Considerations

### **Cost vs. Quality**

Balance your budget with the quality required for your project. While extruded acrylic is cheaper, it may not offer the same level of durability and optical clarity as cast acrylic. Evaluate the long-term benefits and costs associated with each type.

### **Bulk Purchasing**

If you need a large quantity of acrylic sheets, purchasing in bulk can reduce costs. Many suppliers offer discounts for larger orders, making it economical for extensive projects.

## Conclusion

Choosing the right acrylic sheet involves careful consideration of your project requirements, including the type of acrylic, thickness, color, finish, and special properties. By understanding these factors, you can make an informed decision that ensures the success and longevity of your project. Whether you're crafting, building, or designing, the right acrylic sheet can make all the difference.